Feetech Servos

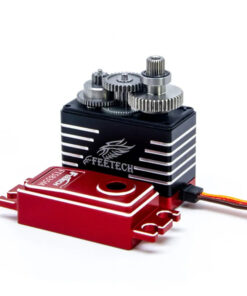

Precision Motion: Why Feetech Servos are the Go-To for FPV and RoboticsWhen you’re building a gimbal for long-range surveillance or a custom gripper for a recovery drone, the feetech servo lineup offers the best balance between cost and reliability. Whether you need the brute force of a feetech 35kg servo or the nimble footprint of a feetech fs90 micro servo, these motors provide the precise PWM control required for modern flight controllers and microcontrollers. Don’t forget to check our New FPV Arrivals for the latest frames to mount these on.Feetech Servo Compatibility MatrixChoosing the right motor depends on your voltage overhead and torque requirements. Below is a technical breakdown of the most popular Feetech models.ModelTypeTorque (6V)Rotation RangeBest Use CaseFS90Analog Micro1.5 kg.cm180° PositionalLightweight FPV Pan/TiltFS90RDigital Micro1.3 kg.cm360° ContinuousSmall Wheeled RobotsFS5103RStandard3.2 kg.cm360° ContinuousWinch Systems / DIY RoversFS5115MHigh Torque15.5 kg.cm180° PositionalHeavy Duty Gimbals / SteeringFT5335MUltra Torque35.0 kg.cm180° PositionalLarge Scale RC / IndustrialStep-by-Step Setup: Wiring Your Feetech Smart ServoMost feetech servo motor units follow the standard 3-pin wiring convention (Ground, VCC, Signal). To avoid the dreaded “brownout” during high-load maneuvers, follow these steps:Verify Voltage: Most Feetech minis operate at 4.8V – 6V. Running a feetech high-torque servo fs5115m directly off a 4S LiPo will smoke the internal H-bridge instantly.Signal Frequency: Set your PWM frequency to 50Hz for analog models. Digital models like the feetech scs0009 servos can handle higher refresh rates, but 50Hz is the safe baseline.Current Draw: High-torque models can pull over 2A under stall. Ensure your BEC is rated for the peak current, not just the idle current. Use quality Drone Tools to crimp secure JST-SH or Dupont connectors.Common Pitfalls: Reddit Insights & Pro-TipsIf you browse the FPV subreddits, the biggest complaint with the continuous rotation servo feetech fs5103r is the “center point drift.” Because these are 360 positional servo feetech units modified for continuous spin, you often need to calibrate the deadband in your code to ensure the motor actually stops when the signal is at 1500us.Another common issue is gear stripping in the feetech fs90r micro continuous rotation servo. While these are great for small projects, they use nylon gears. For high-impact FPV applications, always step up to the metal-geared feetech high torque servo fs5115m to ensure your build survives a rough landing.Feetech Servo FAQWhat is the difference between analog and digital servos?In most simple applications, analog servos will serve your purposes well. However, digital servos like the feetech smart servo series are better for complex motion control because they process signals at a higher frequency (300Hz+), resulting in faster response times and better holding torque.Is a continuous servo analog or digital?They can be either. A continuous rotation servo feetech fs5103r is typically analog, while newer micro models are digital. Digital continuous servos provide much finer control over rotation speed and have less “jitter” around the zero-signal point.Do digital servos use PWM?Yes. Even a high-end feetech 35kg servo uses a digital PWM signal, typically with a 50Hz frame rate for compatibility, though the internal processing of that signal is handled by a digital circuit for better precision.How do I know if my servo is analog or digital?Check the technical drawing or the pulse frequency spec. Digital servos usually send pulses to the motor at 500Hz (every 0.002 seconds), whereas analog servos are limited to the 50Hz input frame rate.