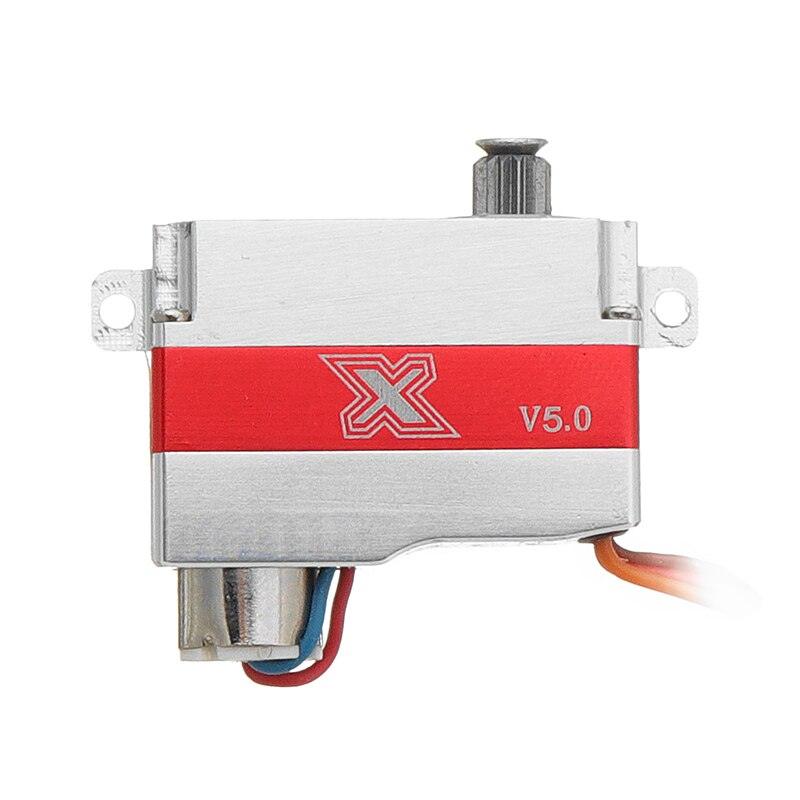

Coreless Servos

What Does a Coreless Servo Mean?

Coreless motors, which are essentially high-performance brushed DC motors, do not have a traditional iron core. Instead, the armature windings form a self-supporting hollow cylinder, which is why they are called “coreless.” This smaller, lightweight, and compact design drastically reduces rotor inertia. This allows for incredibly high acceleration and deceleration rates. When comparing a core vs coreless servo, the absence of the heavy iron core in the latter allows for much faster response times. While a brushless motor uses a permanent magnet rotor and electronically controlled stator windings to eliminate brushes, a coreless motor relies on this hollow rotor design for its unique agility.

The difference between coreless and cored motors is primarily the mass of the internal rotor. Because there is no iron core, these motors are compact in size compared to traditional DC motors. This architecture offers several advantages, including enhanced efficiency, decreased weight, and precise motion control. Furthermore, a digital coreless servo, such as the Savox digit 4096 coreless servo, provides high-resolution positioning. While a continuous servo can turn a full 360 degrees like a motor, standard coreless servos are typically used for precise positional rotation where speed is the priority.

In a coreless vs brushless servo comparison, the brushless variety generally offers better holding power. Conversely, a coreless servo motor may suggest a bit more “give” depending on the load applied. For a pilot building a lightweight racing rig using a specific FPV Frame Kit, the weight savings of coreless technology are often too good to pass up. It appears to be a matter of balancing raw durability against instantaneous reaction speed. To ensure these servos receive the burst current they need for rapid movements, many engineers recommend pairing them with a high-quality 100C Lipo Battery.

Imagine a scenario where you are at the track and your steering feels sluggish. You might reach for your Drone Tools to swap out a standard cored unit for a Savöx digit 4096 coreless servo. The difference in flick-ability is often immediate. However, one must remember that while brushless motors have no brushes to wear out, the coreless digital servo still uses mechanical brushes, which could eventually wear down under extreme racing conditions. This trade-off is why choosing between a servo brushless vs coreless setup requires understanding your specific flight or driving style.

Troubleshooting Your Coreless Digital Servo

Based on community feedback, some coreless servos, like those from Injora, may make noise even when you aren’t touching the controls. This jittering often indicates the servo is struggling to find its center point. If you find you can’t center it properly, it may suggest a worn internal potentiometer or a slight misalignment in the gear train. Another common issue involves durability; while the motors are fast, a hard impact can snap a gear tooth. Some manufacturers have great support but might be slow to ship replacement parts, and in some cases, they don’t sell individual gears at all. If you find yourself with two broken units, you might attempt to merge the working parts of both into one functional servo to get back in the air quickly.