Agriculture Drone Accessories

Precision Agriculture Drone Accessories: Engineering the Future of Smart Farming

In the world of precision agriculture, the difference between a successful harvest and a mechanical failure often lies in the quality of your accessories. Whether you are looking for higher or lower KV motors to optimize torque for heavy payloads or navigating the complex landscape of FCC-compliant US-made components, selecting the right hardware is critical. Our curated selection of accessories ensures your fleet remains operational, efficient, and compliant with evolving aviation standards.

Component Type

Key Specification

Recommended Application

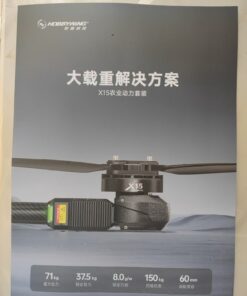

Heavy-Lift Motors

100 – 150 KV (High Voltage)

Large scale spraying & granular spreading

Precision ESCs

80A – 120A (12S – 14S LiPo)

High-torque stability in wind

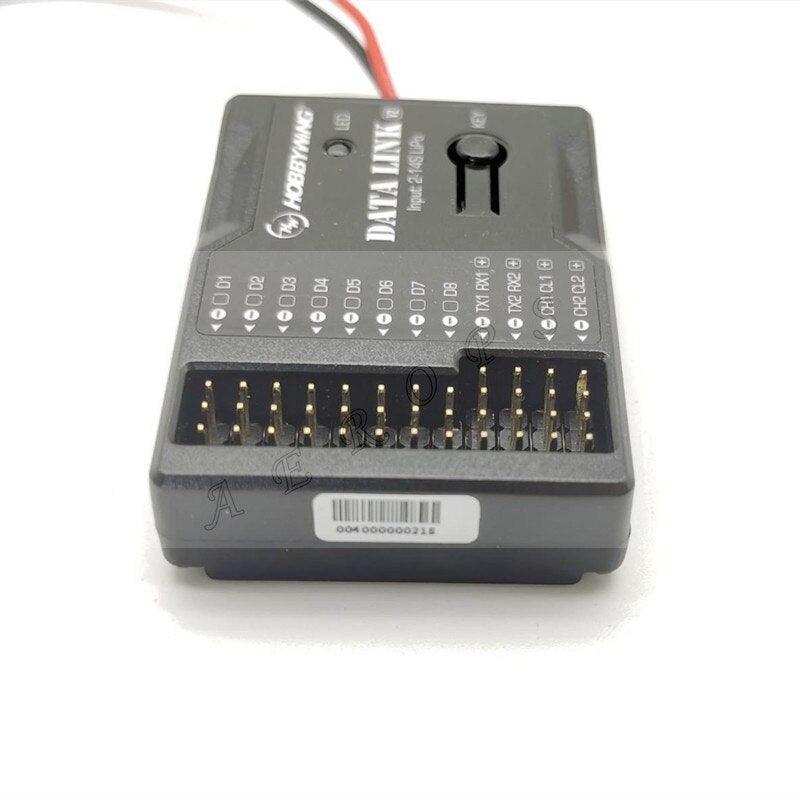

Telemetry Modules

915MHz / 2.4GHz Diversity

Long-range crop monitoring

Power Distribution

A1, A2, S1, S2 Marked Terminals

Industrial DC motor integration

Engineering Analysis: Voltage, KV, and Regulatory Compliance

As a senior engineer, I often get asked: Is higher or lower KV better? For agriculture, lower KV is almost always superior. Lower KV motors allow for larger propellers and higher voltage (more cells), which reduces current draw and heat—crucial for 30-minute spray missions. When wiring DC motors for specialized pumps, understanding that A1 and A2 represent the armature while S1 and S2 denote the series field is vital for reversing polarity without damaging the ESC. For those confused by aviation terminology, SB stands for Service Bulletin, a critical document for maintaining airworthiness, distinct from SIL (Service Information Letter).

Recent shifts in the industry, particularly Reddit-fueled discussions regarding FCC language on foreign components, have made sourcing US-made parts a priority. While some “Made in India” or US-consumer level components can be 30x more expensive and aimed at the defense sector, we bridge the gap by providing tested, reliable accessories that avoid the pitfalls of “overpriced first-gen drones.” We’ve also addressed the CF PLA failure points; our structural accessories avoid the delamination issues common in cheap carbon-fiber filaments, ensuring your Spray Nozzles and Water Pumps stay mounted even under high vibration.

Maximizing the lifespan of your Ag Drone Batteries requires more than just a charger; it requires a systematic approach to voltage management. Remember, 1 kV equals 1,000 volts, but in the FPV world, we focus on the volts-per-cell. A healthy 12S system operates at 44.4V nominal, and maintaining this equilibrium is the key to preventing mid-air power sags during heavy lift operations.

Frequently Asked Questions

What are the parts of an agricultural drone?

Agriculture drones consist of a specialized frame, propulsion systems (motors and propellers), flight controllers, GPS sensors, and specialized payloads like multi-spectral cameras or liquid tanks. High-quality accessories like specialized pumps and nozzles are what turn a standard multi-rotor into a precision farming tool.

How are drones used in smart farming?

Drones are utilized for crop monitoring, precision spraying, and soil analysis. By using thermal and hyperspectral sensors, farmers can identify irrigation issues or pest infestations before they are visible to the naked eye, allowing for targeted input application.

What are the 4 types of drones?

The four primary types are Multi-Rotor (most common for spraying), Fixed-Wing (best for large scale mapping), Single Rotor (heavy lift), and Hybrid VTOL (combining vertical takeoff with efficient forward flight).

How is a drone maintained?

Maintenance involves cleaning motors and propellers after every flight to remove chemical residue, checking for Service Bulletins (SB), and monitoring battery health. Modern smart batteries provide real-time data that should be logged to predict cell failure before it occurs.