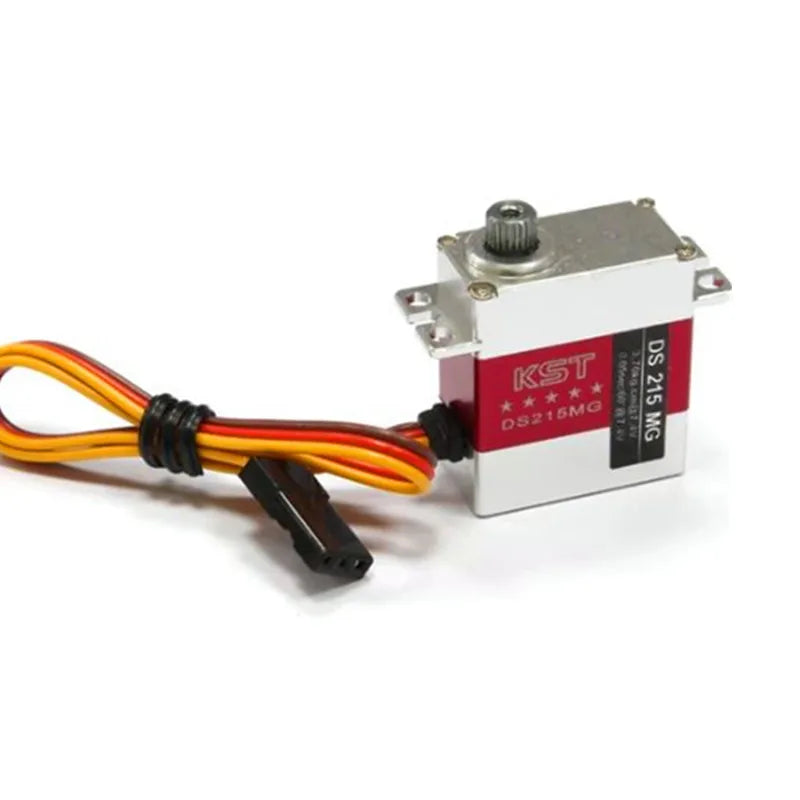

Сервопривод KST

Stop Stripping Gears: Why KST Servos Are the Secret Weapon for High-Performance Builds

If you’ve been in the RC or FPV world for any length of time, you’ve likely experienced the frustration of a budget servo failing mid-flight. As many pilots on Reddit have noted, ‘cheap AliExpress servos’ often suffer from jittery potentiometers or gears that strip at the slightest impact. When you are building a premium Комплект рамы FPV, compromising on your actuators is a recipe for disaster. That is where KST servos come in.

KST has built a reputation for producing high-spec, CNC-machined servos that offer the precision of high-end brands like Futaba or JR, but at a much more accessible price point. Whether you are looking for the ultra-slim KST 06 servo for a DLG wing or the high-torque KST DS215MG servo for a 450-class heli, these units provide the reliability required for aggressive maneuvers.

KST Servo Comparison Chart

Модель

Тип

Torque (6.0V)

Speed (6.0V)

Best For

KST X06

Micro Servo

1.5kg.cm

0.08s/60°

DLG & Small Gliders

KST X08 / A08

Субмикро

2.8kg.cm

0.09s/60°

High-Performance Wings

KST DS215MG

Mini Servo

3.1kg.cm

0.06s/60°

Helis & FPV Tail Servos

Solving Common Pilot Pain Points

One of the biggest complaints in the community is the ‘straight horn’ issue, where a lack of a drag saver or a poor KST servo spline fitment leads to internal damage. To ensure a perfect setup, we recommend using high-quality Drone Tools during installation to properly align your KST servo arm and horn. Furthermore, because high-voltage KST servos draw significant current during peak loads, pairing them with a high-discharge Аккумулятор 100C Lipo ensures your BEC doesn’t brown out during intense 3D flight.

Frequently Asked Questions (FAQ)

Are KST servos any good?

Absolutely. While brands like JR and Futaba offer great service, KST servos are exceptionally well-built and spec’d for the money. They are a favorite in the helicopter and glider communities for their metal gear durability and coreless motor performance.

Where are KST servos made?

KST servos are manufactured in China. They are a leading factory and supplier that focuses on integrating new technologies and CNC designs to stay ahead of the competition in the precision actuator market.

What is a KST A12-T servo?

The KST A12-T is a precision-engineered aluminum mini coreless servo featuring a magnetic sensor. It is designed specifically for large-scale gliders, jet turbines, and high-end aerobatic models where centering accuracy is paramount.

Why are quality servos so expensive?

High-quality servos like KST use specialized components, including CNC-machined aluminum cases and hardened steel gears. The production is more specialized than standard motors, leading to a more limited supply of high-performance units.

What is the lifespan of a KST servo?

While standard industrial servo motors can last 20,000 to 30,000 hours, RC servos are subject to higher vibration. However, thanks to their metal gears and high-quality motors, KST servos significantly outlast budget plastic alternatives.

Pro Tip: Use a KST Servo Programmer

To get the most out of your KST servos review-winning hardware, consider using a KST servo programmer. This allows you to adjust center points, endpoints, and direction, ensuring your control surfaces are perfectly synchronized without stressing the airframe.