Сервоприводы для дронов

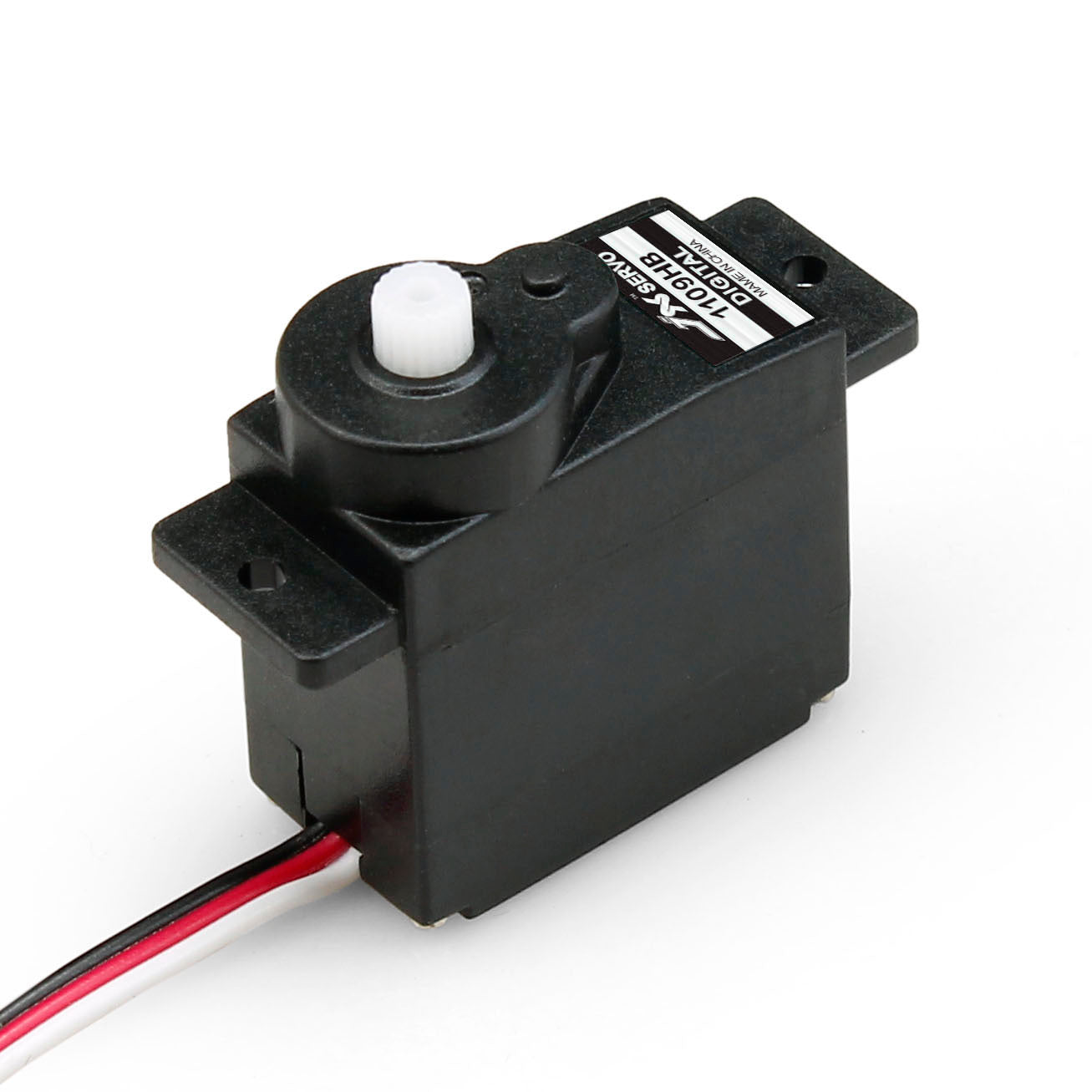

Precision Actuation: High-Torque Drone Servo Motors for Drop Systems & GimbalsWhether you are building a specialized drone servo drop mechanism for delivery or fine-tuning a servo camera drone for cinematography, selecting the right actuator is critical. A high-quality servo motor for drone applications provides the precision needed for angular positioning that standard brushless motors cannot match. If you’re coming from the murder drones discord server or looking to upgrade an s8000 servo drone, understanding the nuances of torque and signal frequency is the first step to a successful build.Drone Servo Compatibility MatrixChoosing between a servo motor drone setup involves balancing speed and holding torque. Use the table below to identify the right hardware for your flight controller (FC) and power distribution system.Servo TypeSignal TypeTypical VoltageBest Use CaseAnalog ServoPWM (50Hz)4.8V – 6.0VBasic drone servo drop systems, simple wingsDigital ServoHigh-Freq PWM6.0V – 8.4V (HV)Precision gimbals, s8000 servo drone app integrationsContinuous RotationVariable PWM5.0VWorm gear mechanisms, 360-degree panningStep-by-Step Guide: Wiring and Mapping Your ServoIntegrating a servo for drone use isn’t always plug-and-play. Follow these engineering steps to ensure your hardware doesn’t brown out your flight controller:Power Management: Never power a servo directly from your FC’s 5V rail. Use a dedicated BEC (Battery Eliminator Circuit) to prevent voltage sag during high-load maneuvers.Resource Mapping: If your FC lacks dedicated PWM pads, many pilots use the ‘resource remapping’ trick in Betaflight. As noted in several drone server discussions, any LED pad can be remapped to a servo output if it has a timer.Signal Configuration: For an s8000 servo drone or custom build, ensure your servo drone tab is enabled in your configuration software. Set the midpoints (usually 1500) and endpoints (1000-2000) to prevent the motor from stalling against mechanical limits.Before your next mission, browse our New FPV Arrivals to find the latest high-current BECs and flight controllers. Having the right Drone Tools on hand will make remapping and soldering these delicate connections much easier.Common Issues & Pro-Engineer TipsBased on real-world feedback from the murder drones server and Reddit communities, servos are often the “slowest” part of a quadcopter build. If you experience the “worm gear sticking” issue, try dialing your roll channel rate back to 70% or 80%. This prevents the gear from over-extending and locking up. Additionally, if you see alternating blue and yellow lights on your s8000 servo drone app while paired but nothing moves, check your channel mapping; often, the FC is looking for servo 1 while the hardware is wired to servo 8.Frequently Asked QuestionsWhat are servos in drones?Servo drives control drone auxiliary functions by sending precise electrical pulses that dictate the motor’s position. This allows for precise speed and direction control, which is essential for adjusting camera angles or releasing payloads.What is the purpose of a servo?A servo motor drone component acts as a rotary or linear actuator. They are mainly used for specific angular positions, velocity, and acceleration in parts like camera gimbals or landing gear.Is a digital or analog servo better?Digital servos are generally superior for modern drones. They offer faster response times and better holding torque, which is vital for advanced motion control and storing sequences in the system’s memory.What is the lifespan of a servo?The lifespan of a servo motor for drone use typically ranges between 20,000 and 30,000 working hours, though this can decrease significantly if the servo is constantly stalled or operated at high temperatures.What kind of fuel do drones use?While the servos are electronic, the drones themselves mostly use Lithium-Polymer (Li-Po) batteries. Larger industrial drones may use hydrogen fuel cells to power the entire electronics suite, including the servos.